Tabasco, Mexico —(Map)

A group called New Story is working with a company called Icon to quickly build lots of houses for poor people who need them. The way they are building the houses is unusual – they are 3D-printing them.

Last year Icon created the first 3D-printed house in the United States built with government permission.

New Story is a group that works to bring cheap but good houses to people who can’t afford them. The group has built over 2,700 houses in places like Bolivia, El Salvador, Haiti, and Mexico.

(Source: New Story/Icon.)

Now Icon and New Story have been showing off two new 3D-printed houses in Tabasco, Mexico. The two small homes are the first in a planned village of 50 3D-printed houses, meant for extremely poor people from the area.

In the past, New Story has had local workers use concrete to build its houses in a more normal way. Those houses cost about $6,500 to build. That’s not much for a house, but the process isn’t fast, which limits the number of houses that New Story can provide.

(Source: Joshua Perez, New Story/Icon.)

That’s why New Story began to work with Icon. Icon has developed a way to build houses quickly by 3D-printing them with concrete.

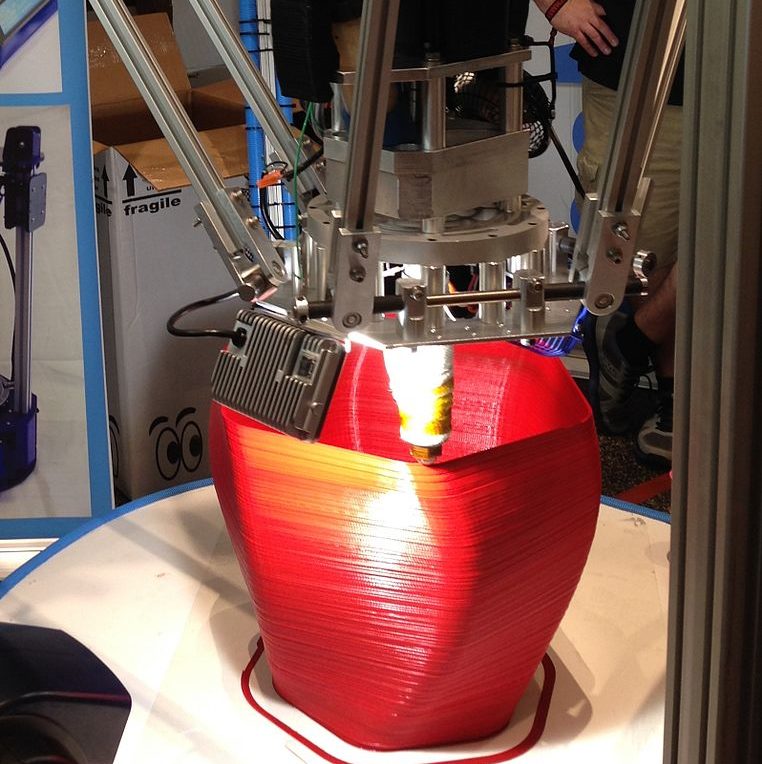

You’ve probably heard of 3D-printing before. Usually, 3D-printing involves a machine that builds something by putting down many layers of a material – often hot plastic. When the material hardens, all the layers stick together to create a finished object.

(Source: Z22 [CC BY-SA 4.0], via Wikimedia Commons.)

Icon’s method works in a similar way, but with concrete. Their printer – a tough machine called Vulcan II – can squirt out round streams of concrete into any needed shape – almost like squeezing toothpaste out of a tube.

The houses are built on a solid concrete base. To construct a house, the Vulcan II squirts out layer after layer of the house’s walls onto the base. The building gets taller as the lower layers harden. The roof, like the base, is not 3D-printed, and must be made in a more normal way.

(Source: Icon.)

The Vulcan II is designed to be tough, so that it can be trucked into faraway areas. The concrete used by Vulcan II is made out of materials that can be found just about anywhere in the world. The location in Tabasco was chosen as a test to see how well the Vulcan II could work in faraway areas.

It worked well. The 500-square-foot (46-square-meter) homes were built in about 24 hours of printing.

(Source: Joshua Perez, New Story/Icon.)

The houses in Tabasco have two bedrooms, a living room, a kitchen, and a bathroom. Because the houses are created with a computer design, it’s easy to change the design to suit the needs of different families. Families are expected to move in next year.

Some areas where New Story wants to build houses suffer from earthquakes, so Icon’s houses have been designed to hold up in earthquake conditions.

(Source: Joshua Perez, New Story/Icon.)

New Story and Icon believe that with practice they can learn to make the houses even more quickly and bring the price of making them down even farther – perhaps as low as $3,500.

😕

This map has not been loaded because of your cookie choices. To view the content, you can accept 'Non-necessary' cookies.